Description

How a tuned mass damper works

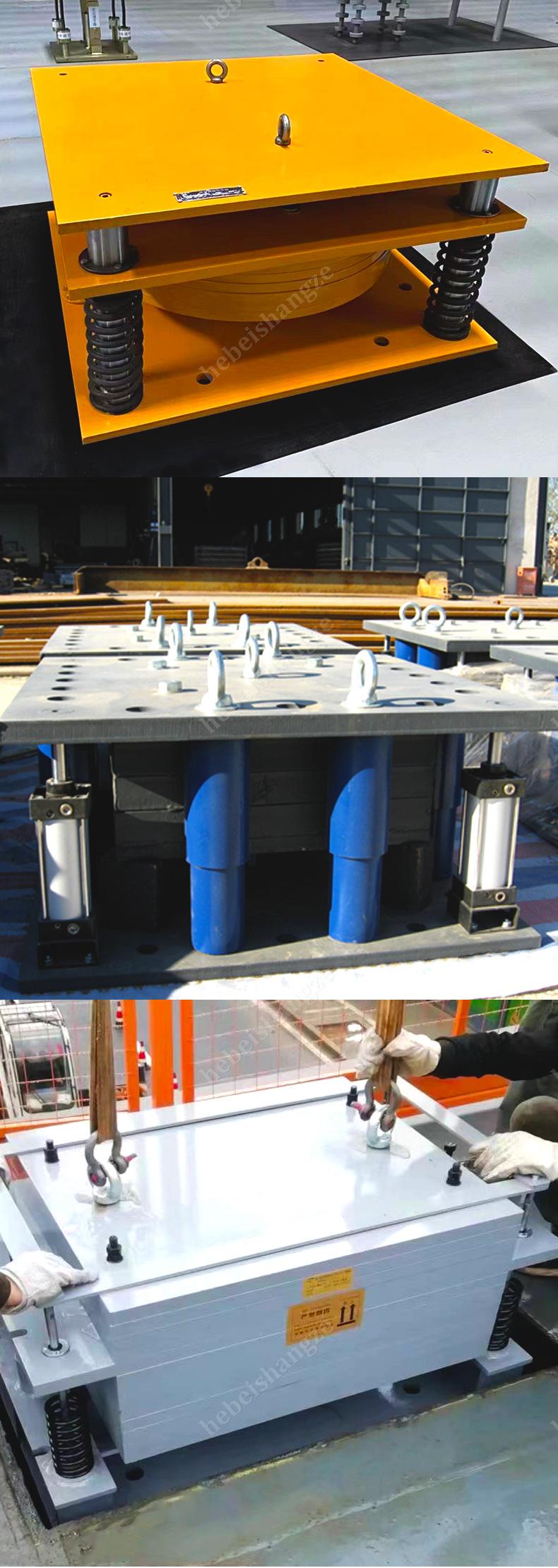

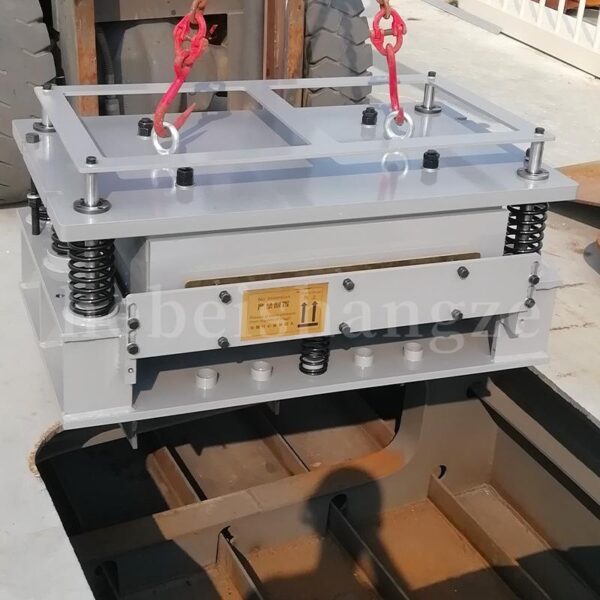

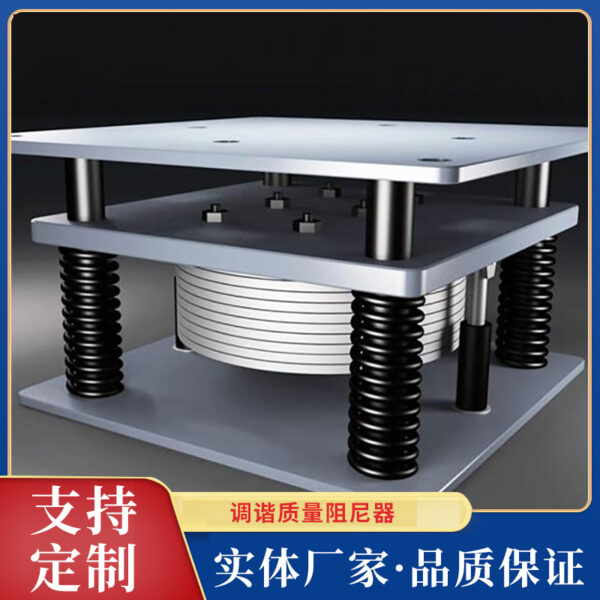

A tuned mass damper (TMD) consists of a mass block, a spring and a damping system. The purpose of installing tuned mass dampers into the structure is to reduce the vibration amplitude of the basic structure under the action of external forces and improve user comfort. In this case, the vibration frequency is generally adjusted to near the frequency of the main structure to change the resonance characteristics of the structure to achieve shock absorption.

A building harmonized mass damper is a device used in building structures, also known as a structural damper or vibration controller. It is mainly used to suppress vibrations of building structures and improve the seismic performance and safety of buildings.

Tuned mass dampers are structural passive control vibration damping devices.

The passive tuned vibration reduction control system is composed of a structure and a substructure attached to the main structure. The additional substructure has mass, stiffness and Pooh, West, and can adjust the natural frequency of the substructure to make it as close as possible to the basic frequency or excitation frequency of the main structure. In this way, when the main structure vibrates due to excitation, the substructure will vibrate. An inertial force opposite to the vibration direction of the main structure is generated to act on the main structure, so that the reaction of the main structure is attenuated and controlled.

Product uses for Building Harmonized Mass Dampers include:

- Reduce the vibration amplitude of the building structure, thereby reducing the impact of external vibrations such as earthquakes on the building.

- Improve the stability and seismic performance of the building and reduce the stress and deformation of the structure.

- Improve building comfort and reduce noise and discomfort caused by structural vibrations.

- Protect the equipment and furnishings inside the building and reduce damage caused by building vibration.

The installation steps of building harmonized mass dampers are as follows:

- Determine the installation location: Determine the specific installation location of the damper based on the characteristics and design requirements of the building structure.

- Install the support structure: According to the size and weight of the damper, design and install a suitable support structure to ensure that the damper can be stably installed in the building structure.

- Connect the damper: According to the design requirements of the damper, connect it to the building structure to ensure that the connection is firm and reliable.

- Debugging and testing: After installing the damper, conduct debugging and testing to check whether the performance and effect of the damper meet the requirements.

- Monitoring and maintenance: After installation, the damper should be monitored and maintained regularly to ensure its normal operation and long-term use.

Precautions:

- When selecting the installation location, consider the load and vibration characteristics of the damper to avoid conflict with other components or equipment.

- During the installation process, attention should be paid to the balance and even distribution of loads to avoid structural problems caused by uneven loads.

- During the installation process, relevant safety regulations and operating requirements must be followed to ensure the personal safety of construction personnel.

- After installation, regular inspection and maintenance of the damper and its connecting parts should be carried out to detect and solve problems in time.

Hebei Shangze, as a professional damper manufacturer, has always been committed to providing high-quality products and excellent services. Before shipping, we will carefully check the quantity and quality of the goods, and use the most convenient and reliable packaging method to ensure the safety of the products during transportation. At the same time, we will provide full tracking service, if you have any problems or questions during the transportation, please feel free to contact us. Every customer’s order is very important to us and we will make every effort to ensure your satisfaction.

Thank you again for your support and we look forward to establishing a long-term cooperative relationship with you.

Hebei Shangze Rubber and Plastic Products Co., Ltd. is a modern enterprise integrating the R&D, production and sales of rubber and plastic products. The company is located in the High-tech Zone, Hengshui City, Hebei Province, in the southeast of Hebei Province, in the hinterland of the North China Plain, with Bordering Beijing, Tianjin, and Shijiazhuang, and close to the national arteries Beijing-Kowloon and Shijiazhuang Railway, the transportation is very convenient. The company mainly produces steel skeleton composite pipes, pile foundation acoustic pipes, prestressed corrugated pipes, plastic corrugated pipes, silicon core pipes, steel fiber series, drainage pipes, bridge guardrail brackets, bridge bearing deceleration and isolation products, and expansion joint devices. products, waterstop products, waterstop strips and other products. Each series of products can be processed and manufactured according to drawings. The company has advanced technology, sophisticated equipment, assembly line operations, and excellent product quality.

Shopkeeper’s promise

The products in this store are taken in kind, and there may be slight differences due to display reasons.;This store ensures that all products are quality guaranteed

about the price

Since there are many product models and different specifications, the prices of the products are also different. We support customization but please explain.model, we can calculate the price for you more accurately. Please contact customer service for specific prices(The product price attribute on this page is onlyFor reference, please contact customer service or Telecom for details.)。

about delivery fee

Our goods are all heavy goods with different specifications and shipping costs. The specific shipping costs are subject to customer service quotations. Need deliveryPlease contact customer service in advance(Unless the customer requires the freight to be paid by default)。

About receiving goods

When receiving the goods, please confirm the product quantity. If there is any problem that does not meet the order requirements, please contact us immediately. If you find that the goods are missing more than ten days after signing for the goods, we will not be able to help you solve the trouble that may be caused by logistics.

About invoicing

The products sold in this store are quoted without tax. If you need to add tax points for invoicing, please contact customer service for details.

evaluation questions

We attach great importance to every evaluation and even more to every customer’s feelings.;If you have any questions after receiving the item, please contactWe, we will try our best to help you deal with it;We will complain to the end if there are malicious negative reviews.!

A damper is a device used to absorb shock and control mechanical motion. It mainly reduces vibration and impact by absorbing and converting kinetic energy. Dampers can be divided into various types according to their working principles and structural characteristics. Several common dampers will be described in detail below.

The first is a friction damper. Friction damper dampens mechanical motion by providing friction. Its main structure includes friction plates, friction plate brackets and elastic elements. When the machine moves, the friction between the friction plate and the friction plate bracket generates resistance, thereby slowing down the movement speed. Friction dampers have the characteristics of simple structure, stability and reliability, and are widely used in bicycles, doors and windows, etc.

The second type is a metal composite damper, which is a structural damper usually composed of metal materials and damping materials. Its functions mainly include the following aspects: Shock absorption: Metal composite dampers can absorb and disperse the vibration and impact energy of the structure, thereby reducing the vibration amplitude and fluctuation of the structure and protecting the safety and stability of the structure. Energy consumption effect: Metal composite dampers convert vibration or impact energy into heat energy through the elastic deformation of the structure and the loss of metal materials, thereby dissipating energy and reducing the vibration intensity of the structure. Adjustment and control function: The damping characteristics of metal composite dampers can control and adjust structural vibration through the selection of materials and adjustment of design parameters, and improve the dynamic performance of the structure. Enhanced seismic resistance: Metal composite dampers can increase the seismic resistance and shock absorption capacity of the structure, allowing the structure to effectively resist vibration under the action of external forces such as earthquakes, and reduce structural damage and damage. Metal composite dampers mainly control and eliminate structural vibration and impact through shock absorption, energy dissipation, adjustment and control, and improve the structure’s seismic resistance and stability. Its application in engineering structures can effectively reduce the damage and damage caused by vibration to the structure and protect the safe and reliable operation of the structure.

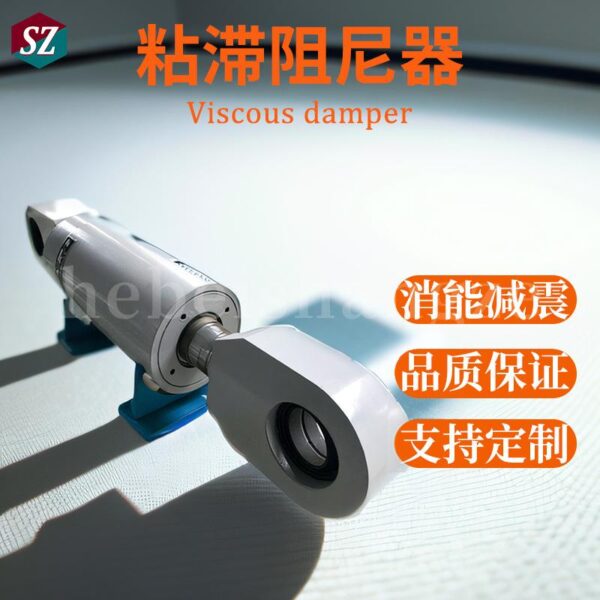

The third type is viscous damper, a device used to reduce vibration and impact. Its functions mainly include the following aspects: Shock absorption: Viscous damper can absorb and disperse vibration and impact energy, thereby reducing the damage of the structure or equipment. Vibration and impact amplitude, protecting the safety and stability of structures or equipment. Slow down the movement speed: The viscous resistance of the oil inside the viscous damper can slow down the movement speed of the structure or equipment and generate damping force during the movement, thereby effectively reducing the speed and impact force of the movement. Energy dissipation: Viscous dampers convert vibration or impact energy into heat energy, and achieve energy dissipation through the friction and flow of materials inside the viscous damper, thereby reducing the vibration and impact amplitude of the structure or equipment. Adjustment and control function: The damping characteristics of the viscous damper can control and adjust the vibration and impact of the structure or equipment by adjusting the viscosity of the oil or adjusting the design parameters of the damper. Viscous dampers mainly control and eliminate vibration and impact through shock absorption, deceleration, energy dissipation and control and adjustment, and improve the performance and reliability of structures or equipment.

The fourth type is that the tuned mass damper is widely used in engineering structures to suppress resonance: the tuned mass damper can effectively suppress the resonance phenomenon of the structure, prevent the structure from excessive amplitude or destructive vibration under external force excitation, and improve the structure stability and security. Reduce the dynamic response of the structure: The tuned mass damper can adjust the natural frequency of the system to make the dynamic response of the structure smaller under external force excitation and reduce the vibration level of the structure. Absorb vibration energy: Tuned mass dampers can absorb and convert the vibration energy of the structure into other forms of energy (such as heat energy), thereby reducing the dynamic response of the structure and protecting structures and equipment. Improve the fatigue life of the structure: Tuned mass dampers can reduce the stress and deformation of the structure, reduce the fatigue damage rate of the structure, and extend the service life of the structure. In short, tuned mass dampers can effectively control the vibration response of the structure, improve the dynamic characteristics of the structure, and improve the safety and reliability of the structure.

The fifth type is metal yield damper, which mainly absorbs and dissipates energy through the elastic deformation of metal to reduce structural vibration. Its main functions include shock absorption: when the structure is subject to earthquakes, wind loads or other external excitations, metal yield dampers can absorb the vibration energy of the structure, thereby reducing the amplitude and time of structural vibration, and reducing the risk of structural damage and collapse. Vibration reduction effect: The metal yield damper has a good vibration reduction effect on the low-frequency vibration of the structure, which can effectively reduce the resonance phenomenon of the structure and avoid damage to the structure caused by resonance. Energy absorption: When the structure is subjected to a large vibration force, the metal yield damper can absorb and dissipate energy through the yielding and plastic deformation process of the metal, protecting the structure from damage. Increase the stability of the structure: Metal yield dampers can improve the seismic and wind-resistant performance of the structure and increase the stability and safety of the structure. Reduce the dynamic response of the structure: Metal yield dampers can reduce the dynamic response of the structure by absorbing and dissipating vibration energy, reduce the response of the structure to excitations such as earthquakes, and improve the stability and safety of the structure. Metal yield dampers mainly improve the stability and safety of the structure through shock absorption, vibration reduction, energy absorption, etc., reduce the vibration response of the structure, and protect the structure from damage by external excitations.

The sixth type is the coupling beam damper. The coupling beam damper is a device installed on the building structure. Its function is to reduce the transmission of shock and vibration by providing damping force. It can be used in various types of buildings, including residential buildings, commercial buildings and large infrastructure such as bridges and towers.

In short, dampers can be divided into various types according to their working principles and structural characteristics, including friction dampers, metal composite dampers, viscous dampers, tuned mass dampers, metal yield dampers, etc. They play different roles in their respective fields and are very important for shock absorption and control of mechanical movements. In practical applications, people can choose the appropriate damper type according to specific needs to ensure the stable operation, safety and reliability of mechanical equipment.

Reviews

There are no reviews yet.