Rubber waterstop is a material used to prevent water leakage. It is usually used in waterproof sealing operations such as basements, underground pipes, toilets, and toilets in construction projects. Its main function is to prevent moisture penetration and to withstand a certain amount of pressure.

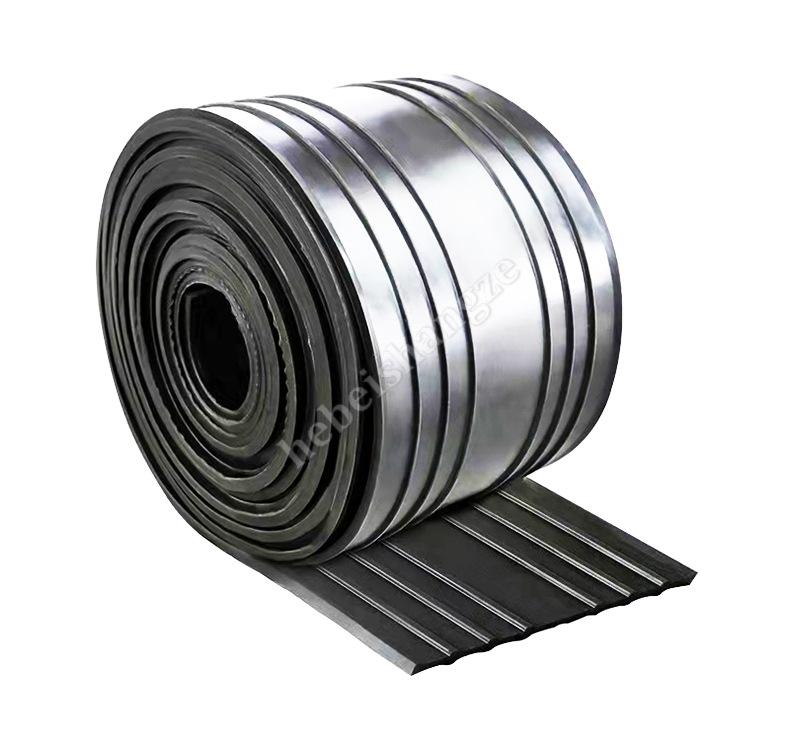

Rubber waterstop: Rubber waterstop is made of rubber material and has excellent elasticity and aging resistance. It can effectively prevent water leakage and is suitable for various building structures, especially concrete components that use more binders.

oakThe product parameters of glue waterstops usually include the following aspects:

-

Dimensions: including length, width and thickness. Different sizes of rubber waterstops are suitable for different construction needs, and the appropriate size can be selected according to the specific project.

-

Material: Rubber or rubber composite material is generally used as the main material. The material of the rubber waterstop must have good elasticity, chemical corrosion resistance, heat resistance, cold resistance, aging resistance and other properties.

-

Sealing performance: including compression deformation rate and rebound performance. The compression deformation rate refers to the compression deformation ability of the rubber waterstop during construction, and the resilience energy refers to the ability of the rubber waterstop to return to its original shape from a compressed state.

-

Chemical corrosion resistance: Rubber waterstops need to have good chemical corrosion resistance and can withstand certain corrosive substances, such as acids and alkalis.

-

Heat resistance: Rubber waterstops need to have a certain degree of heat resistance to maintain elasticity and sealing performance in high temperature environments.

-

Cold resistance: The rubber waterstop needs to have a certain degree of cold resistance and be able to maintain elasticity and sealing performance in low temperature environments.

-

Usage environment: including indoor or outdoor use environment, as well as applicable building types and construction locations, etc.

Rubber waterstop has the following main functions:

-

Waterproof sealing: Rubber materials have good sealing properties and can be used to fill cracks and gaps in building structures to prevent moisture penetration.

-

Chemical corrosion resistance: The material of the rubber waterstop has good chemical corrosion resistance and can be used for a long time in acid and alkali environments without being corroded and losing its sealing performance.

-

Heat and cold resistance: Rubber waterstops can maintain good elasticity and sealing performance in high and low temperature environments, and will not be deformed or damaged due to temperature changes.

-

Anti-aging: Rubber materials have strong anti-oxidation and anti-ultraviolet capabilities, and can resist aging and deterioration during long-term outdoor use.

-

Pressure resistance: Rubber waterstops can withstand a certain pressure and can bear a certain weight in underground buildings while maintaining sealing performance.

Construction and installation of rubber waterstops

Waterstops are partially or fully embedded in the concrete during the concrete pouring process. Since there are many sharp-edged stones and steel bars in concrete, during the process of waterstop positioning and concrete pouring, attention should be paid to the installation positioning method and pouring pressure to prevent the waterstop from being punctured. Since the tear strength of rubber is lower than the tensile strength3-5times, so if the waterstop is punctured, the ability of the waterstop to resist external forces will be greatly reduced. Therefore, special attention should be paid during construction.

Specific precautions are as follows:

1) When tying steel bars and formwork, the waterstop must be reliably fixed to avoid displacement when pouring concrete and ensure the correct position of the waterstop in the concrete.

2)When fixing the waterstop, you can only make holes in the permitted parts of the waterstop and do not damage the main body.

3)The fixing method of the waterstop should be carried out according to the construction specifications required by the design. Commonly used fixing methods include:Secure with additional steel bars;Special clamp fixation;Fix with lead wire and template, etc. No matter what fixing method is used, it is necessary to ensure that the waterstop is positioned accurately, without damaging the effective part of the waterstop, and to facilitate concrete pouring.

Hebei Shangze, as a professional waterstop manufacturer, has always been committed to providing high-quality products and excellent services. Before shipping, we will carefully check the quantity and quality of the goods, and use the most convenient and reliable packaging method to ensure the safety of the products during transportation. At the same time, we will provide full tracking service, if you have any problems or questions during the transportation, please feel free to contact us. Every customer’s order is very important to us and we will make every effort to ensure your satisfaction.

Thank you again for your support and we look forward to establishing a long-term cooperative relationship with you.

Hebei Shangze Rubber and Plastic Products Co., Ltd. is a modern enterprise integrating the R&D, production and sales of rubber and plastic products. The company is located in the High-tech Zone, Hengshui City, Hebei Province, in the southeast of Hebei Province, in the hinterland of the North China Plain, with Bordering Beijing, Tianjin, and Shijiazhuang, and close to the national arteries Beijing-Kowloon and Shijiazhuang Railway, the transportation is very convenient. The company mainly produces steel skeleton composite pipes, pile foundation acoustic pipes, prestressed corrugated pipes, plastic corrugated pipes, silicon core pipes, steel fiber series, drainage pipes, bridge guardrail brackets, bridge bearing deceleration and isolation products, and expansion joint devices. products, waterstop products, waterstop strips and other products. Each series of products can be processed and manufactured according to drawings. The company has advanced technology, sophisticated equipment, assembly line operations, and excellent product quality.

The products in this store are taken in kind, and there may be slight differences due to display reasons.;This store ensures that all products are quality guaranteed

about the price

Since there are many product models and different specifications, the prices of the products are also different. We support customization but please explain.model, we can calculate the price for you more accurately. Please contact customer service for specific prices(The product price attribute on this page is onlyFor reference, please contact customer service or Telecom for details.)。

about delivery fee

Our goods are all heavy goods with different specifications and shipping costs. The specific shipping costs are subject to customer service quotations. Need deliveryPlease contact customer service in advance(Unless the customer requires the freight to be paid by default)。

About receiving goods

When receiving the goods, please confirm the product quantity. If there is any problem that does not meet the order requirements, please contact us immediately. If you find that the goods are missing more than ten days after signing for the goods, we will not be able to help you solve the trouble that may be caused by logistics.

About invoicing

The products sold in this store are quoted without tax. If you need to add tax points for invoicing, please contact customer service for details.

evaluation questions

We attach great importance to every evaluation and even more to every customer’s feelings.;If you have any questions after receiving the item, please contactWe, we will try our best to help you deal with it;We will complain to the end if there are malicious negative reviews.!

Waterstop is a very practical building material and is widely used for waterstop treatment in construction projects. Its main function is to prevent water leakage and ensure the structural safety of the building and the service life of the building materials. In construction projects, waterstops are usually used in the following areas: separation strips, expansion joints, broken bridges and crack treatment.

First of all, waterstops serve as separation strips and are mainly used to separate different parts to effectively isolate different building materials and structures. This helps prevent water leakage between different parts, which can lead to structural damage to the building and water seepage problems in the walls. The use of waterstops can make the building structure stronger and more stable, and increase the service life of the building.

Secondly, waterstops are also widely used in the treatment of expansion joints. In construction projects, temperature changes, earthquakes, or expansion and contraction of building materials can cause expansion and contraction of building structures. In order to avoid the damage caused by these expansions and contractions to the building, the application of waterstops plays an important role. By installing waterstops at expansion joints, water penetration at the expansion joints can be effectively isolated, protecting the structural safety of the building, and reducing repair and maintenance costs.

In addition, waterstops are often used to deal with broken bridges. Broken bridge position refers to the overall or partial damage to thermal insulation and sound insulation. In order to repair the broken bridge and prevent water leakage, the use of waterstops has become an indispensable part. It can effectively fill the gap in the broken bridge position, prevent water penetration, and at the same time improve the thermal insulation performance and sound insulation performance of the building.

Finally, crack treatment is also an important use of waterstops. During the use of buildings, cracks of various shapes and sizes often appear due to various reasons, such as foundation settlement, temperature changes, etc. In order to prevent cracks from continuing to expand and prevent water from penetrating, the use of waterstops plays a key role. By installing waterstops at cracks, you can effectively prevent water leakage and protect the structural safety of the building.

Waterstops can be divided into the following types according to different materials:

1. Rubber waterstop: Rubber waterstop is made of rubber material and has excellent elasticity and aging resistance. It can effectively prevent water leakage and is suitable for various building structures, especially concrete components that use more binders.

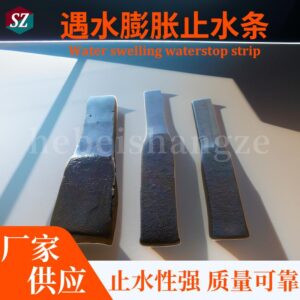

2. Composite water-stop strip that swells when exposed to water:It is a water-stop product made of special materials, usually composed of a variety of polymer materials and inorganic substances. It is widely used in construction, underground engineering, water conservancy engineering and other fields to prevent water leakage in basements, tunnels, pools, dams and other parts.

3. Steel edge waterstop:Steel edge waterstop is a waterstop product made of rubber material and steel strip. Widely used in water stop treatment in construction projects,IncludingSeparation treatment of concrete structures、Treatment of concrete expansion joints、Blocking treatment of underground engineering、Water stop treatment for pools and water conservancy projects。

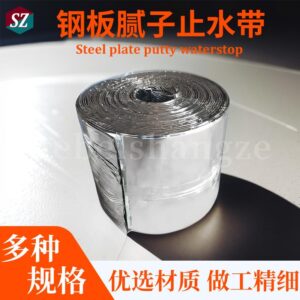

4.Steel plate putty waterstop: It is composed of steel plate and putty material. Steel plates are usually made of galvanized or stainless steel, and putty materials can be various Portland cements, polymers, polyurethanes, etc., which are used to fill gaps in the steel plates and act as a water stop. Mainly used in water-stop projects of buildings and structures, such as dams, underground projects, pools, tunnels, etc. It can effectively prevent water penetration and leakage, protecting the safety and stability of the structure.

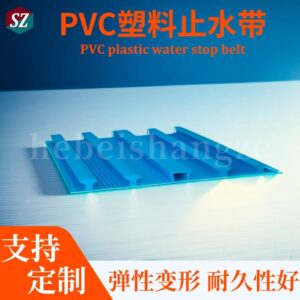

5.PVCplasticWaterstop:PVC waterstop is made of polyvinyl chloride material and has excellent corrosion resistance and weather resistance. It is widely used in basements, tunnels, pools and other environments, and can effectively prevent water leakage.

6.Product waterstop:Product waterstopIt is not the name of a specific material, but a general term for waterstops made of various materials. Common product waterstops include rubber waterstops, plastic waterstops, fiber material waterstops, etc.

7.Putty water stop strip:Putty waterstop strips are generally made of polymer composite materials containing putty materials. Putty water-stop strips are often used in water-stop projects in underground pools, basements, tunnels, underground pipes, etc. During the construction process, putty water-stop strips are often embedded in gaps or used in combination with other building materials, such as concrete, masonry, etc., to achieve a complete water-stop effect. At the same time, putty water-stop strips can also resist certain temperature changes, ultraviolet radiation and chemical corrosion, and have good durability.

8.Anti-slurry strip:Grout stopper is a material used in building construction, usually a long strip made of rubber or plastic. It is mainly used to control the flow of concrete slurry during construction and prevent concrete overflow or loss.

In addition to the above common types, there are also waterstops made of other special materials according to specific usage scenarios and needs, such as polyether type, polyurethane type, etc. No matter what type of waterstop is used, it is necessary to choose the appropriate product according to the specific situation to ensure that it has a good waterproof effect.

As a manufacturer of waterstops, our company provides various types of waterstop products. Our waterstops are made of high-quality materials with excellent temperature resistance, corrosion resistance and aging resistance. Our products not only have excellent water-stopping effects, but are also easy to install and have a long service life. Whether it is separation strips, expansion joints, bridge breaks or crack treatment, we can provide suitable product solutions.

We are committed to providing customers with high-quality waterstop products and providing a full range of after-sales services to ensure customer satisfaction. You are welcome to choose our products. We believe that our waterstop products can provide comprehensive protection for your construction projects, making them stronger and safer. By purchasing our products, you will get high-quality products and a value-for-money shopping experience.

বাংলা

বাংলা 简体中文

简体中文 English

English Français

Français Deutsch

Deutsch Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 Português

Português Русский

Русский Español

Español ไทย

ไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.