Ordinary rubber bearings are made of natural rubber sheets or chloroprene rubber sheets laminated with steel plates. They have good linear properties and can significantly reduce the seismic effects of the structure and suppress the high dielectric reaction of the structure. This type of support does not provide damping. It is difficult to move the support seat during an earthquake. In actual projects, it must be used in conjunction with various dampers.。

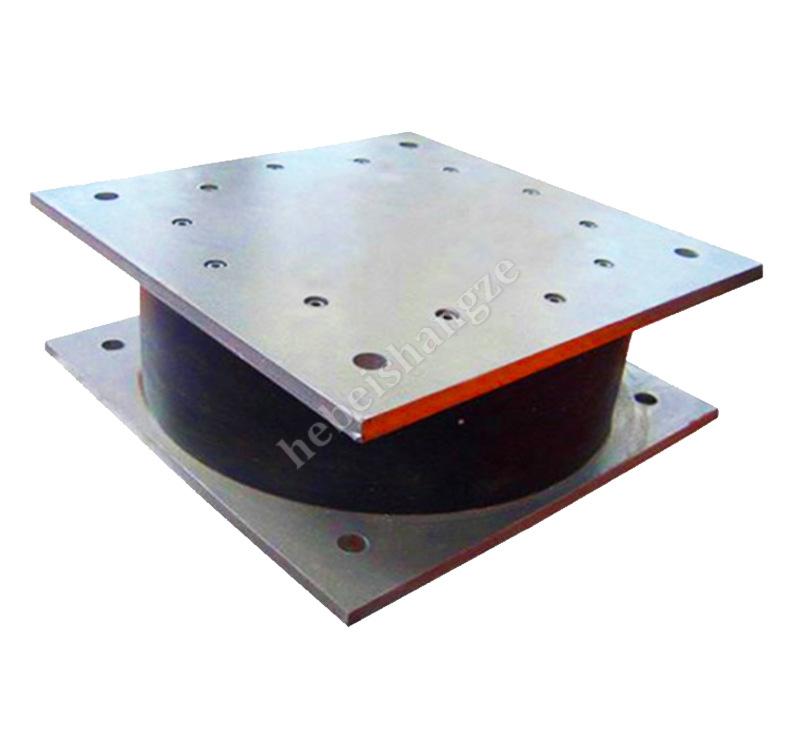

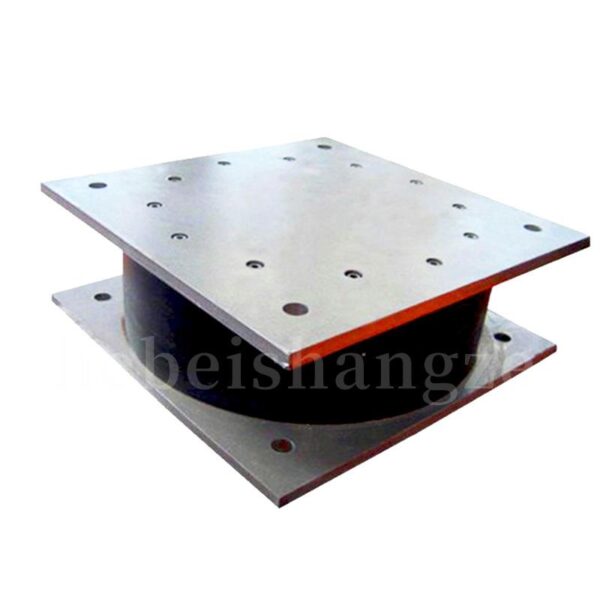

The building isolation bearing product is a special bearing used in the earthquake isolation design of buildings. Its main purpose is to protect buildings from earthquakes. By installing isolation bearings, the vibration force experienced by buildings during earthquakes can be reduced and the structure of the building and the safety of personnel can be protected.

A seismic isolation bearing is a seismic isolation device made of rubber material. It is highly compressible and deformable, and can quickly absorb and disperse energy during earthquakes, thereby reducing the vibration of buildings. Rubber isolation bearings usually consist of one or more layers of rubber gaskets that can be adjusted as needed to meet different load and vibration requirements.

A seismic isolation bearing is a seismic isolation device made of rubber material. It is highly compressible and deformable, and can quickly absorb and disperse energy during earthquakes, thereby reducing the vibration of buildings. Rubber isolation bearings usually consist of one or more layers of rubber gaskets that can be adjusted as needed to meet different load and vibration requirements.

Seismic isolation bearing is a device commonly used in building and bridge structures. Its main function is to reduce the impact of earthquakes, wind loads and other dynamic loads on the building structure, thereby providing higher structural stability and safety. Seismic isolation bearings can effectively isolate the energy transmitted from seismic waves to the structure, reduce post-earthquake damage, and protect the integrity of the building and its internal equipment.

The installation steps of the isolation bearing are as follows:

-

Preparation work: Confirm the structural and design requirements of the building, and determine the type and quantity of earthquake isolation supports.

-

Determine the installation position: According to the design requirements, determine the installation position of the isolation bearing and mark the center point of the bearing.

-

Trim the foundation: According to the size of the isolation bearing, trim and smooth the surface of the foundation to be installed, and ensure that the surface of the foundation is not damaged.

-

Install the fixing bolts: Pre-embed the fixing bolts on the surface of the foundation, arrange them according to the requirements of the isolation bearing, and ensure that the bolts are firmly connected to the foundation.

-

Install the isolation bearing: Place the isolation bearing on the foundation, align the fixing bolt holes, and use a wrench to connect the isolation bearing to the fixing bolts.

-

Adjust the height of the support: According to the design requirements, use adjustment bolts or adjustment pads to adjust the height of the isolation support to ensure a smooth connection between the support and the upper part of the structure.

-

Repeated inspection and fixation: Repeatedly check the installation position, height and fixation firmness of the isolation bearing, and perform final fixation after adjustment.

-

Completion acceptance: After completing the installation of the isolation bearing, carry out relevant acceptance work to ensure that the installation quality meets the design and specification requirements.

Hebei Shangze, as a professional manufacturer of building isolation bearings, has always been committed to providing high-quality products and excellent services. Before shipping, we will carefully check the quantity and quality of the goods, and use the most convenient and reliable packaging method to ensure the safety of the products during transportation. At the same time, we will provide full tracking service, if you have any problems or questions during the transportation, please feel free to contact us. Every customer’s order is very important to us and we will make every effort to ensure your satisfaction.

Thank you again for your support and we look forward to establishing a long-term cooperative relationship with you.

Hebei Shangze Rubber and Plastic Products Co., Ltd. is a modern enterprise integrating the R&D, production and sales of rubber and plastic products. The company is located in the High-tech Zone, Hengshui City, Hebei Province, in the southeast of Hebei Province, in the hinterland of the North China Plain, with Bordering Beijing, Tianjin, and Shijiazhuang, and close to the national arteries Beijing-Kowloon and Shijiazhuang Railway, the transportation is very convenient. The company mainly produces steel skeleton composite pipes, pile foundation acoustic pipes, prestressed corrugated pipes, plastic corrugated pipes, silicon core pipes, steel fiber series, drainage pipes, bridge guardrail brackets, bridge bearing deceleration and isolation products, and expansion joint devices. products, waterstop products, waterstop strips and other products. Each series of products can be processed and manufactured according to drawings. The company has advanced technology, sophisticated equipment, assembly line operations, and excellent product quality.

Shopkeeper’s promise

The products in this store are taken in kind, and there may be slight differences due to display reasons.;This store ensures that all products are quality guaranteed

about the price

Since there are many product models and different specifications, the prices of the products are also different. We support customization but please explain.model, we can calculate the price for you more accurately. Please contact customer service for specific prices(The product price attribute on this page is onlyFor reference, please contact customer service or Telecom for details.)。

about delivery fee

Our goods are all heavy goods with different specifications and shipping costs. The specific shipping costs are subject to customer service quotations. Need deliveryPlease contact customer service in advance(Unless the customer requires the freight to be paid by default)。

About receiving goods

When receiving the goods, please confirm the product quantity. If there is any problem that does not meet the order requirements, please contact us immediately. If you find that the goods are missing more than ten days after signing for the goods, we will not be able to help you solve the trouble that may be caused by logistics.

About invoicing

The products sold in this store are quoted without tax. If you need to add tax points for invoicing, please contact customer service for details.

evaluation questions

We attach great importance to every evaluation and even more to every customer’s feelings.;If you have any questions after receiving the item, please contactWe, we will try our best to help you deal with it;We will complain to the end if there are malicious negative reviews.!

Seismic isolation bearing is a device commonly used in building and bridge structures. Its main function is to reduce the impact of earthquakes, wind loads and other dynamic loads on the building structure, thereby providing higher structural stability and safety. Seismic isolation bearings can effectively isolate the energy transmitted from seismic waves to the structure, reduce post-earthquake damage, and protect the integrity of the building and its internal equipment.

Seismic isolation bearings can be divided into many types according to their structure and materials. The most common types include rubber isolation bearings,Lead isolationsupport,High damping rubber bearing、Elastic shock-absorbing bearings and tensile friction pendulum shock-absorbing isolation bearings.

Rubber isolation bearing is a kind of isolation device made of rubber material. It is highly compressible and deformable, and can quickly absorb and disperse energy during earthquakes, thereby reducing the vibration of buildings. Rubber isolation bearings usually consist of one or more layers of rubber gaskets that can be adjusted as needed to meet different load and vibration requirements. Rubber isolation bearings also offer the advantages of long service life, low maintenance costs and high reliability.

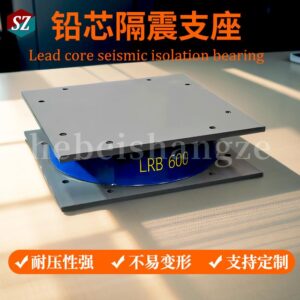

Lead core isolation bearings consist of an outer steel bearing and an inner lead core. Steel bearings are often made from high-strength steel and are designed to withstand gravity loads and other non-seismic loads from a building or bridge. The lead core serves as a seismic isolation component and has good seismic isolation capabilities. The main function of the lead core is to convert seismic force or vibration energy into heat energy through its lower stiffness and good energy absorption performance when earthquakes or other external vibrations occur, thereby reducing the vibration force experienced by buildings or bridges. . It should be pointed out that the quality and size of lead-core isolation bearings need to be strictly controlled during the design and installation process to ensure their working effect and safety. In practical applications, structural engineers need to reasonably select and calculate the number, size, and layout of isolation bearings based on the characteristics and seismic conditions of the specific building or bridge to achieve the isolation effect.

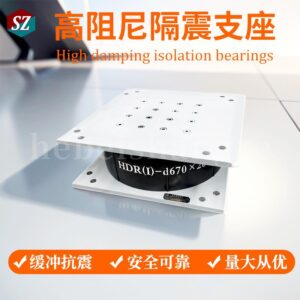

The high-damping rubber bearing consists of an outer metal container and an inner lead rubber material. The outer container is usually made of steel or aluminum alloy and has sufficient strength and stability. The internal lead rubber material is a high-damping material with low stiffness and good energy absorption capabilities. It dissipates the energy of earthquakes or other vibrations through the elastic deformation of rubber and frictional damping of the internal metal container.

Elastic shock-absorbing bearing, also known as elastic bearing or rubber bearing, is a shock-absorbing device used in building structures. Its main function is to reduce the stress on the building structure and protect the safety of buildings and personnel by absorbing and dispersing energy under the action of earthquakes or other external forces. Elastic shock-absorbing bearings are usually made of rubber materials and have excellent elastic properties and durability. Its basic structure consists of two upper and lower metal plates clamped by rubber gaskets to provide vertical support under static load. When earthquakes or other external forces act on a structure, the gaskets deform through twisting or compression, absorbing and dissipating energy. In this way, the elastic shock-absorbing bearing can reduce the impact force on the structure and effectively reduce the vibration response of the structure.

Friction pendulum isolation bearing is a kind of earthquake isolation device used in building structures. It mainly achieves the seismic isolation effect by using friction and swing, reducing the stress on the building structure under earthquakes or other external forces, and reducing the destructiveness of earthquakes to buildings.

In general, as an important structural device, the isolation bearing can effectively reduce the impact of earthquakes and other dynamic loads on the building structure and improve the stability and safety of the building. Rubber isolation bearings,Lead core isolation bearing、High damping rubber bearing、Elastic shock-absorbing bearings and tensile friction pendulum shock-absorbing isolation bearingsThey are currently the main seismic isolation devices used. Each has different structural and material characteristics and can be selected and applied according to project requirements.

Reviews

There are no reviews yet.