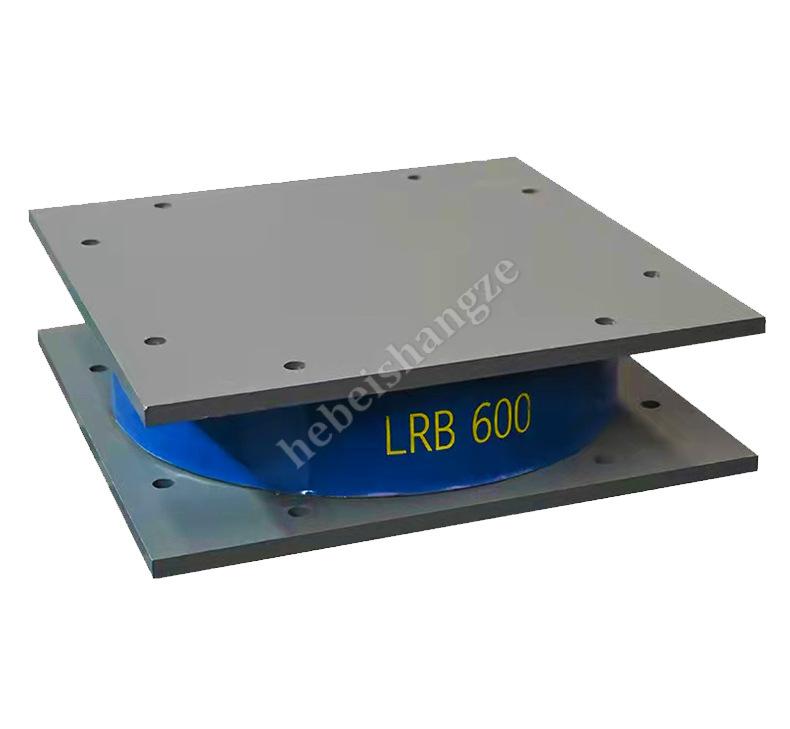

The difference between lead-core isolation bearings and ordinary isolation bearings is that a hole is made in the middle of ordinary isolation bearings, and lead is poured into them to form lead-core rubber bearings. This type of bearing not only has a high damping ratio, but also has a certain initial stiffness, which can provide the building with earthquake and wind resistance.

Lead core isolation bearing is a kind of seismic isolation and vibration reduction device, mainly composed of rubber and lead core. Its main use is in buildings, bridges, mechanical equipment and other structures for shock absorption and isolation, and to reduce the sensitivity of the structure to earthquakes and other vibrations.

Lead core isolation bearings consist of an outer steel bearing and an inner lead core. Steel bearings are often made from high-strength steel and are designed to withstand gravity loads and other non-seismic loads from a building or bridge. The lead core serves as a seismic isolation component and has good seismic isolation capabilities.

The main function of the lead core isolation bearing is to convert the seismic force or vibration energy into heat energy through its lower stiffness and good energy absorption performance when an earthquake or other external vibration occurs, thereby reducing the stress on the building or bridge. withstand the vibration force.

The installation steps are as follows:

-

Preparation: Prepare the required lead core isolation bearings and accessories according to the design requirements.

-

Clean the installation area: Clean the installation area to make sure the surface is flat, clean, and clear of any debris and dirt.

-

Mounting the bearing: Place the lead core isolation bearing on the prepared mounting area. Use shims or bearing caps for padding as required by the design.

-

Adjust the position of the support: After determining the position of the support, use a level or adjustment tool to adjust the level of the support.

-

Fix the support: Fix the support to the structure or foundation by bolts or welding. Make sure it is firmly fixed and adjust the preload as required.

-

Connection structure: If necessary, connect the structure to the lead-core isolation bearing to ensure the stability and sealing of the connection.

-

Acceptance and testing: After the installation is completed, the bearings and structure will be accepted, and corresponding tests and adjustments will be made to ensure the isolation effect of the bearings and the stability of the structure.

Precautions:

- Pay attention to safety during installation to avoid harming yourself and others.

- Lead core isolation bearings should be inspected before installation to ensure that there is no damage or defects.

- Operate according to design requirements to ensure correct connection and fixation of supports and structures.

Hebei Shangze, as a professional lead-core isolation bearing manufacturer, has always been committed to providing high-quality products and excellent services. Before shipping, we will carefully check the quantity and quality of the goods, and use the most convenient and reliable packaging method to ensure the safety of the products during transportation. At the same time, we will provide full tracking service, if you have any problems or questions during the transportation, please feel free to contact us. Every customer’s order is very important to us and we will make every effort to ensure your satisfaction.

Thank you again for your support and we look forward to establishing a long-term cooperative relationship with you.

Hebei Shangze Rubber and Plastic Products Co., Ltd. is a modern enterprise integrating the R&D, production and sales of rubber and plastic products. The company is located in the High-tech Zone, Hengshui City, Hebei Province, in the southeast of Hebei Province, in the hinterland of the North China Plain, with Bordering Beijing, Tianjin and Shijiazhuang, and close to the national arteries Beijing-Kowloon and Shijiazhuang Railway, the transportation is very convenient. The company mainly produces steel skeleton composite pipes, pile foundation acoustic pipes, prestressed corrugated pipes, plastic corrugated pipes, silicon core pipes, steel fiber series, drainage pipes, bridge guardrail brackets, bridge bearing deceleration and isolation products, and expansion joint devices. products, waterstop products, waterstop strips and other products. Each series of products can be processed and manufactured according to drawings. The company has advanced technology, sophisticated equipment, assembly line operations, and excellent product quality.

Shopkeeper’s promise

The products in this store are taken from real objects, and there may be slight differences due to the display ; Our store ensures that all products are of guaranteed quality

about the price

Due to the large number of product models and different specifications, the prices of the products are also different. We support customization, but please specify Model, we can calculate the price for you more accurately. Please contact customer service for specific prices ( The product price attribute on this page is only For reference, please contact customer service or Telecom for details. ) 。

about delivery fee

Our goods are all heavy goods with different specifications and shipping costs. The specific shipping costs are subject to customer service quotations. Need delivery Please contact customer service in advance ( Unless the customer requires the freight to be paid by default ) 。

About receiving goods

When receiving the goods, please confirm the product quantity. If there is any problem that does not meet the order requirements, please contact us immediately. If you find that the goods are missing more than ten days after signing for the goods, we will not be able to help you solve the trouble that may be caused by logistics.

About Invoicing

The products sold in this store are quoted without tax. If you need to add tax points for invoicing, please contact customer service for details.

evaluation questions

We attach great importance to every evaluation and even more to every customer’s feelings. ; If you have any questions after receiving the product, please contact We, we will try our best to help you deal with it ; We will file a complaint against malicious negative reviews !

Seismic isolation bearing is a device commonly used in building and bridge structures. Its main function is to reduce the impact of earthquakes, wind loads and other dynamic loads on the building structure, thereby providing higher structural stability and safety. Seismic isolation bearings can effectively isolate the energy transmitted from seismic waves to the structure, reduce post-earthquake damage, and protect the integrity of the building and its internal equipment.

Lead isolation

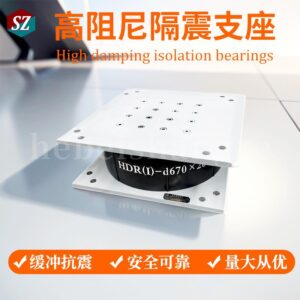

High damping rubber bearing

Elastic shock-absorbing bearings and tensile friction pendulum shock-absorbing isolation bearings.

Rubber isolation bearing is a kind of isolation device made of rubber material. It is highly compressible and deformable, and can quickly absorb and disperse energy during earthquakes, thereby reducing the vibration of buildings. Rubber isolation bearings usually consist of one or more layers of rubber gaskets that can be adjusted as needed to meet different load and vibration requirements. Rubber isolation bearings also offer the advantages of long service life, low maintenance costs and high reliability. Seismic isolation bearings can be divided into many types according to their structure and materials. The most common types include rubber isolation bearings, Lead core isolation bearings consist of an outer steel bearing and an inner lead core. Steel bearings are often made from high-strength steel and are designed to withstand gravity loads and other non-seismic loads from a building or bridge. The lead core serves as a seismic isolation component and has good seismic isolation capabilities. The main function of the lead core is to convert seismic force or vibration energy into heat energy through its lower stiffness and good energy absorption performance when earthquakes or other external vibrations occur, thereby reducing the vibration force experienced by buildings or bridges. . It should be pointed out that the quality and size of lead-core isolation bearings need to be strictly controlled during the design and installation process to ensure their working effect and safety. In practical applications, structural engineers need to reasonably select and calculate the number, size and layout of isolation bearings based on the characteristics and seismic conditions of the specific building or bridge to achieve the isolation effect. support, The high-damping rubber bearing consists of an outer metal container and an inner lead rubber material. The outer container is usually made of steel or aluminum alloy and has sufficient strength and stability. The internal lead rubber material is a high-damping material with low stiffness and good energy absorption capabilities. It dissipates the energy of earthquakes or other vibrations through the elastic deformation of rubber and frictional damping of the internal metal container. 、

Elastic shock-absorbing bearing, also known as elastic bearing or rubber bearing, is a shock-absorbing device used in building structures. Its main function is to reduce the stress on the building structure and protect the safety of buildings and personnel by absorbing and dispersing energy under the action of earthquakes or other external forces. Elastic shock-absorbing bearings are usually made of rubber materials and have excellent elastic properties and durability. Its basic structure consists of two upper and lower metal plates clamped by rubber gaskets to provide vertical support under static load. When earthquakes or other external forces act on a structure, the gaskets deform through twisting or compression, absorbing and dissipating energy. In this way, the elastic shock-absorbing bearing can reduce the impact force on the structure and effectively reduce the vibration response of the structure.

Friction pendulum isolation bearing is a kind of earthquake isolation device used in building structures. It mainly achieves the seismic isolation effect by using friction and swing, reducing the stress on the building structure under earthquakes or other external forces, and reducing the destructiveness of earthquakes to buildings.

Lead core isolation bearing

High damping rubber bearing

Elastic shock-absorbing bearings and tensile friction pendulum shock-absorbing isolation bearings

They are currently the main seismic isolation devices used. Each has different structural and material characteristics and can be selected and applied according to project requirements. In general, as an important structural device, the isolation bearing can effectively reduce the impact of earthquakes and other dynamic loads on the building structure and improve the stability and safety of the building. Rubber isolation bearings, 、 、 、 、 是目前主要采用的隔震装置,各自具有不同的结构和材料特点,可根据项目需求进行选择和应用。

Reviews

There are no reviews yet.