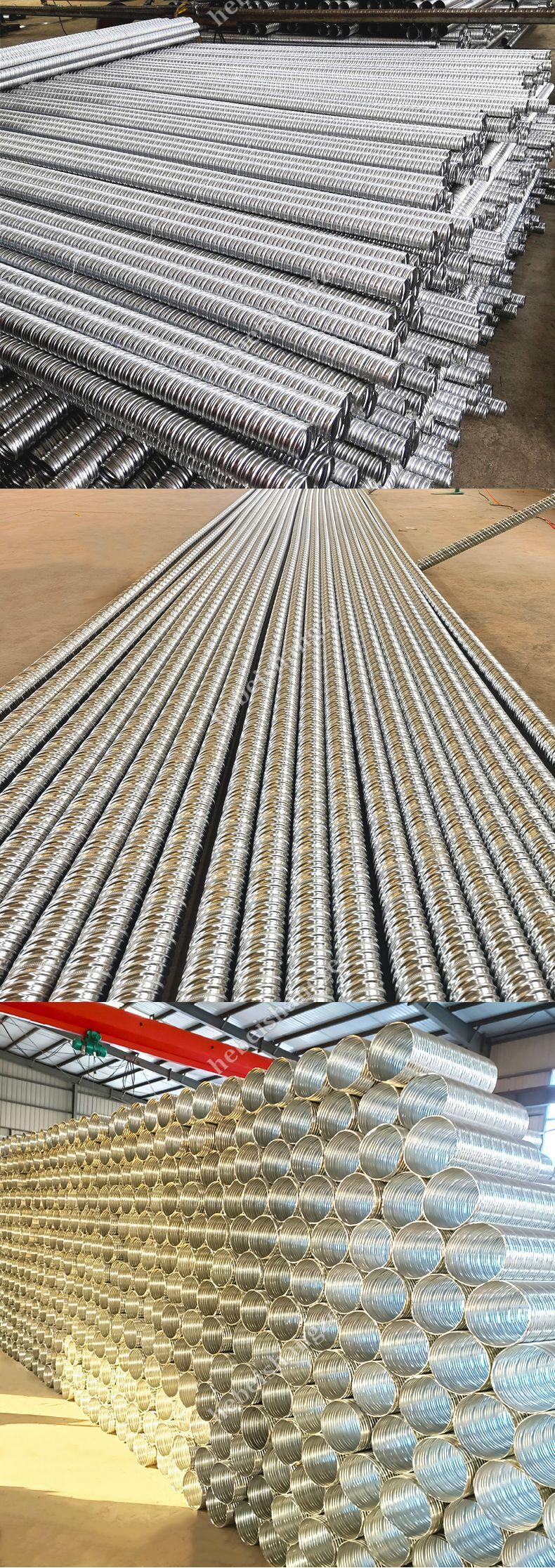

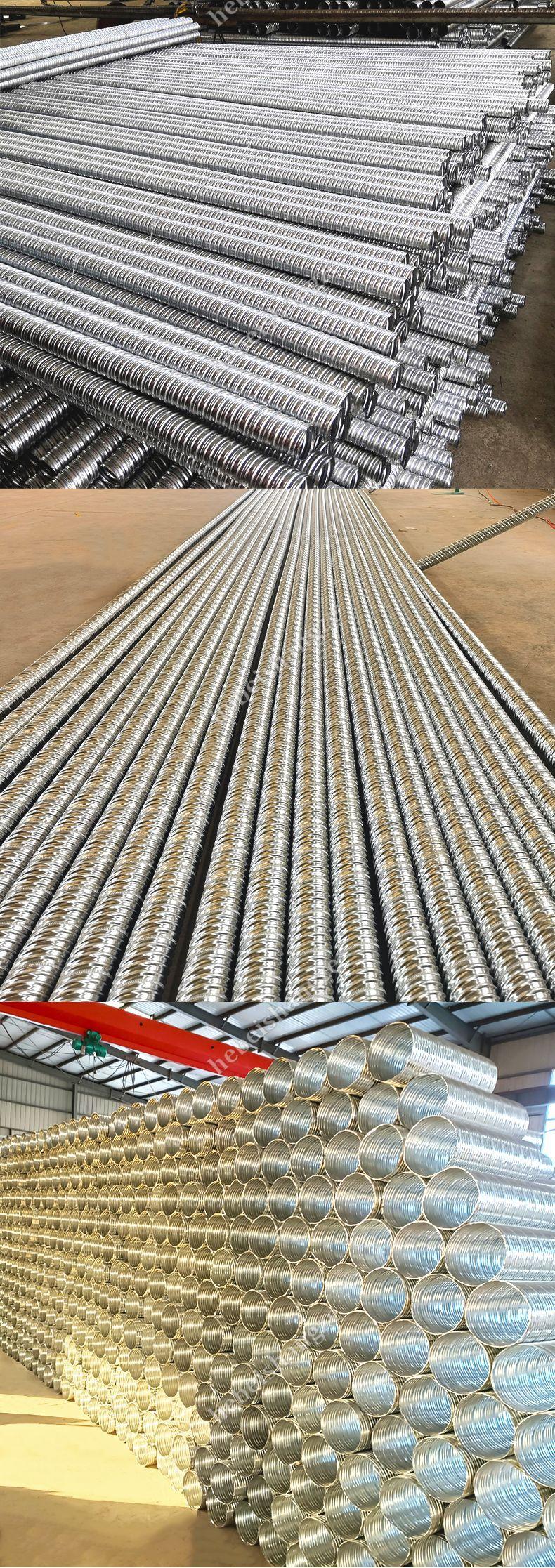

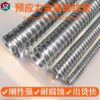

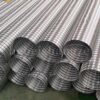

Metal corrugated pipe culverts are made by pressing the surface of 2.5-7.0mm thin steel plates into corrugations and then rolling them into pipe sections. This can increase the stiffness of the pipe sections and the resistance to pipe axis pressure. The culvert built with such pipe sections is called Bellows culvert. Corrugated pipe is a flexible structure with certain earthquake resistance and can adapt to large settlement and deformation.

Advantages of metal corrugated culverts

(1) On-site installation is easy and does not require the use of large equipment.

(2) Helpfully solve the problem of frost damage to bridges and pipe-culvert concrete structures in northern areas.

(3) The use of conventional building materials such as cement, yellow sand, gravel, and wood is reduced or completely abandoned, which has far-reaching environmental significance.

(4) The stress condition of the structure is reasonable, the load distribution is even, and it has a certain ability to resist deformation. (5) Using standardized design, production and design are simple, and the production cycle is short.

Metal corrugated pipe is a metal corrugated pipe culvert. It is a flexible pipe product made of metal materials after pressing the 2.5-7.0mm thin steel plate into corrugations and rolling it into pipe sections. It has good flexibility, corrosion resistance and high temperature resistance. performance

The main uses include the following aspects:

-

Smoke exhaust system: Metal corrugated pipes can be used in building smoke exhaust systems to discharge smoke, waste gas and other harmful gases.

-

Sewage discharge system: Metal corrugated pipes can be used in sewage discharge systems such as sewage treatment plants and industrial production sites to discharge sewage, wastewater, etc.

-

Gas transmission system: Metal corrugated pipes can be used in gas transmission systems to transport natural gas, coal gas and other combustible gases.

-

Water supply system: Metal corrugated pipes can be used in water supply systems to transport clean water, industrial water and other liquids.

-

Petroleum, chemical and other industries: Metal corrugated pipes can be used in pipeline systems for transporting oil, natural gas, chemical liquids, etc.

The installation steps are as follows:

-

Preparation work: According to the pipeline design requirements, prepare the required metal corrugated pipes and accessories.

-

Clean the trenches: Clean the trenches in the installation area to make sure they are dry, flat and clean.

-

Install the bracket: According to the design requirements, install the bracket at the appropriate location to support the metal bellows.

-

Install the connecting parts: If necessary, connect the metal bellows to the connecting parts and fix them by threading, welding, etc.

-

Straighten the metal bellows: During the installation process, pay attention to straightening the metal bellows to ensure that the pipe is neat, straight and free of distortion.

-

Connect the pipe system: According to the design requirements, connect the metal corrugated pipe to other pipe systems to ensure the sealing and stability of the connection.

-

Testing and acceptance: Conduct pressure testing of the pipeline system in accordance with regulations and conduct acceptance to ensure the normal operation of the metal bellows.

Precautions:

- Pay attention to safety during installation to avoid harming yourself and others.

- Metal bellows and connections should be inspected before installation to ensure there are no damages or defects.

- During the installation process, operations must be carried out according to the design requirements, and no deviation or random changes are allowed.

- If necessary, seek professional guidance and help.

Hebei Shangze, as a professional prestressed metal corrugated pipe manufacturer, has always been committed to providing high-quality products and excellent services. Before shipping, we will carefully check the quantity and quality of the goods, and use the most convenient and reliable packaging method to ensure the safety of the products during transportation. At the same time, we will provide full tracking service, if you have any problems or questions during the transportation, please feel free to contact us. Every customer’s order is very important to us and we will make every effort to ensure your satisfaction.

Thank you again for your support and we look forward to establishing a long-term cooperative relationship with you.

Hebei Shangze Rubber and Plastic Products Co., Ltd. is a modern enterprise integrating the R&D, production and sales of rubber and plastic products. The company is located in the High-tech Zone, Hengshui City, Hebei Province, in the southeast of Hebei Province, in the hinterland of the North China Plain, with Bordering Beijing, Tianjin, and Shijiazhuang, and close to the national arteries Beijing-Kowloon and Shijiazhuang Railway, the transportation is very convenient. The company mainly produces steel skeleton composite pipes, pile foundation acoustic pipes, prestressed corrugated pipes, plastic corrugated pipes, silicon core pipes, steel fiber series, drainage pipes, bridge guardrail brackets, bridge bearing deceleration and isolation products, and expansion joint devices. products, waterstop products, waterstop strips and other products. Each series of products can be processed and manufactured according to drawings. The company has advanced technology, sophisticated equipment, assembly line operations, and excellent product quality.

Shopkeeper’s promise

The products in this store are taken in kind, and there may be slight differences due to display reasons.;This store ensures that all products are quality guaranteed

about the price

Since there are many product models and different specifications, the prices of the products are also different. We support customization but please explain.model, we can calculate the price for you more accurately. Please contact customer service for specific prices(The product price attribute on this page is onlyFor reference, please contact customer service or Telecom for details.)。

about delivery fee

Our goods are all heavy goods with different specifications and shipping costs. The specific shipping costs are subject to customer service quotations. Need deliveryPlease contact customer service in advance(Unless the customer requires the freight to be paid by default)。

About receiving goods

When receiving the goods, please confirm the product quantity. If there is any problem that does not meet the order requirements, please contact us immediately. If you find that the goods are missing more than ten days after signing for the goods, we will not be able to help you solve the trouble that may be caused by logistics.

About invoicing

The products sold in this store are quoted without tax. If you need to add tax points for invoicing, please contact customer service for details.

evaluation questions

We attach great importance to every evaluation and even more to every customer’s feelings.;If you have any questions after receiving the item, please contactWe, we will try our best to help you deal with it;We will complain to the end if there are malicious negative reviews.!

Pipe series refers to various pipe materials of different calibers and materials used in engineering.These includeMetal corrugated pipes, steel frame composite pipes, steel mesh composite pipes, hole mesh steel strip composite pipes, silicon core pipes, and steel strip reinforced corrugated pipes all play different roles in engineering.

1.Metal bellows: Metal bellows is a pipe made of corrugated metal pipes. It has good flexibility and scalability and can be used to transport high-temperature and high-pressure media, absorb noise and vibration, etc.

Function: Metal bellows can withstand high pressure and are often used in aerospace, petrochemical, mechanical equipment and other fields. They are used to transport steam, gas, water and other media, and can absorb vibration, reduce noise, adjust pipeline compensation, etc. .

2.Steel frame composite pipe: Steel frame composite pipe is a composite pipe with a steel frame covered inside and outside. The outer layer is often made of plastic or rubber materials.

Function: Steel frame composite pipe has strong pressure resistance, wear resistance, corrosion resistance and other characteristics. It is often used to transport oil, gas, chemicals, sewage and other media. It is widely used in municipal engineering, rural water supply, building drainage and other fields.

3.Steel mesh composite pipe: Steel mesh composite pipe is a pipe composed of steel mesh and plastic materials, which has good compression and tensile properties.

Function: Steel wire mesh composite pipes are used in earthwork projects, sewage discharge projects and other occasions that require resistance to erosion and pressure. They can be used for drainage, river lining, bank slope protection, etc.

4.Perforated steel strip composite pipe: The perforated steel strip composite pipe is a steel strip composite pipe wrapped by a perforated mesh structure, which has good filtration and drainage properties.

Function: Perforated steel strip composite pipes are often used in geotechnical, water conservancy, environmental and other projects. They can be used for drainage, anti-seepage, and filtration, and can also protect the soil, maintain water and soil, and make the project more stable.

5.Silicon core tube: Silicon core tube is a kind of pipe with high temperature resistance and chemical corrosion resistance. It is often used in special industrial fields.

Function: Silicon core tubes are often used to transport high-temperature media, such as petrochemical industry, metallurgy and other fields. They have the characteristics of corrosion resistance, high temperature resistance, extrusion resistance, flexibility and other characteristics.

6.Steel strip-reinforced corrugated pipe is a corrugated pipe reinforced with steel strips, that is, a steel strip is added to the outer layer of the corrugated pipe to enhance its strength and stability.

Steel strip reinforced corrugated pipes play the following roles in engineering:

(1)Strength enhancement: Due to the addition of steel strip reinforcement, the corrugated pipe has higher pressure resistance and impact resistance, improving the stability and reliability of the pipeline system.

(2)Corrosion resistance: Using corrosion-resistant materials, the steel belt-reinforced corrugated pipe has good corrosion resistance and is suitable for the transportation of corrosive media.

(3)Good flexibility and stretchability: Due to the corrugated structure and the addition of steel strips, the pipe has good flexibility and stretchability, adapting to the expansion and contraction deformation of the pipe.

(4)Reduce vibration and noise: Steel belt reinforced corrugated pipes can absorb and reduce vibration and noise in the pipeline system, improving the quietness and stability of the system.

(5)Cost saving: Compared with traditional metal pipes, steel strip reinforced corrugated pipes have lower costs and are easy to install, saving time and cost in project construction.

Steel belt-reinforced corrugated pipes are widely used in construction, petrochemical industry, chemical industry, sewage treatment and other fields to transport various media. They have the characteristics of enhanced strength, corrosion resistance, flexible expansion and contraction, and can ensure the stable operation and safety of the pipeline system. .

The selection of pipe series in the project depends on the specific project requirements, such as the nature of the transport medium, temperature, pressure requirements, material cost, etc. You can choose according to various materials and functions.

Reviews

There are no reviews yet.