Customer visit our factory

In August 12th, Shandong customer come to Hebei Shangze rubber and plastic co.,ltd and visit our friction Pendulum Isolation Bearing factory!

General Manager Luan warmly entertain our customer, answer the questions, and helped to establish a long-term and stable cooperation with Shandong customers.

In order to help you better understand the friction pendulum, I will analyze the product from the structure of friction pendulum, the working principle of friction pendulum and the application of friction pendulum support.

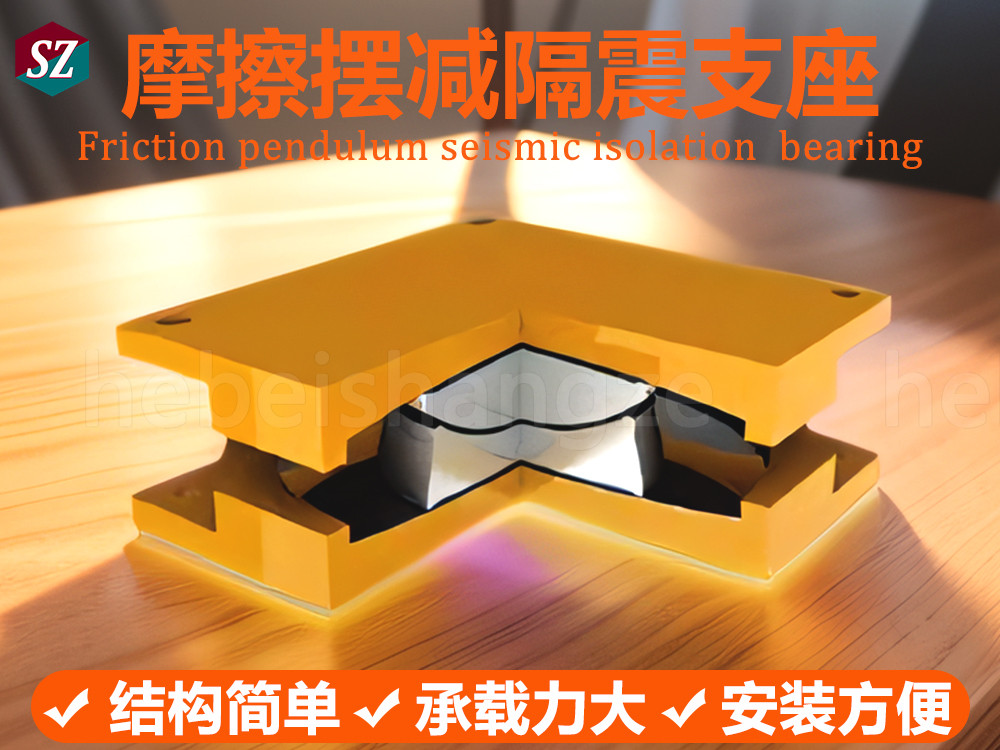

Structure and Components of Friction Pendulum Bearings

Friction pendulum isolation spherical bearings generally consist of upper bearing plates, stainless steel plates, upper wear-resistant plates, spherical crowns, lower wear-resistant plates, rubber sealing rings, lower bearing plates, shear plate components and anchoring components.

Our company’s friction pendulum isolation spherical bearings are divided into the following three types in terms of structure and function, and each can be designed into a one-way, two-way, universal, or fixed structure to facilitate the designer’s choice:Shangze rubber-plastic friction pendulum shock-absorbing isolation bearing has a simple structure and clear shock-absorbing mechanism. It is suitable for structures that have no tension and only slide to reduce and isolate earthquakes.

The friction pendulum isolation bearing is composed of a certain number of friction plates and guide devices. When the structure undergoes horizontal displacement under the action of earthquakes or other vibrations, friction will occur between the friction plates. The friction force can convert the kinetic energy of the structure into thermal energy, thereby reducing the vibration response. At the same time, the guide device can limit the vertical displacement of the structure and ensure the stability of the structure.

Working Principle of Friction Pendulum Bearing

A friction pendulum bearing is a type of seismic isolation device designed to reduce the seismic forces transmitted to a structure during an earthquake. It achieves this by converting the horizontal component of earthquake-induced forces into frictional heat energy.

How it works:

(1)Basic Structure: A friction pendulum bearing typically consists of an upper and lower plate, connected by a spherical sliding element. The sliding element is housed within a concave surface on the lower plate.

(2)Seismic Event: When an earthquake occurs, the structure above the bearing moves horizontally. This relative movement causes the spherical sliding element to roll within the concave surface.

(3)Friction and Energy Dissipation: As the sliding element rolls, friction is generated between the sliding surfaces. This friction dissipates the seismic energy, preventing it from being transmitted to the structure.

(4)Hysteretic Behavior:The force-displacement relationship of a friction pendulum bearing exhibits a hysteretic behavior, meaning that the force required to displace the bearing depends on its previous loading history. This hysteretic behavior helps to dissipate energy effectively.

The application of Friction Pendulum Bearing

Friction Pendulum Bearings (FPBs) have become increasingly popular in seismic engineering due to their exceptional performance in isolating structures from earthquake ground motions. Their application spans a wide range of structures, including:

Bridges

Bridges are critical infrastructure that must remain operational after an earthquake. FPBs can protect bridge components from damage and ensure continued functionality.

hospitals

Hospitals require uninterrupted operation even after a seismic event. FPBs can safeguard patient care by isolating the building and preventing structural damage.

Industrial Facilities

Industrial facilities often house hazardous materials and equipment. FPBs can protect these facilities from earthquake damage, reducing the risk of environmental hazards.

Cultural Heritage Buildings

Preservation of historical and cultural heritage buildings is crucial. FPBs can protect these irreplaceable structures from seismic damage.

FPBs are also used in:

Schools and universities

Government buildings